Capable of simulating line screens up to 220 lpi, Star Proof is well known for reproducing the sharpest dots possible on an Epson proofer. Star Proof will show the same dot produced by your RIP on your proofer, in just the way they will show once printed on your press. But, did you know that Star Proof can reproduce spot colors with a high degree of accuracy?

The new EPSON Sylus Pro 7900/9900 and WT7900 offer an incredibly larger color gamut than previous plotters. This is due to the additional inks these plotters utilize. Orange and green on the Stylus Pro 7900 and 9900. And white ink on the WT7900. Star Proof 6 takes advantage of this larger color space to accurately reproduce spot colors. Calibrating Star Proof to do this, it's very easy with its optional Packaging Option. Here's how:

With the aid of X-Rite's color port, we create a target made up of all the spot colors that we wish to calibrate. Then we print it and read it using your favorite spectro device - in our case, we used the i1 iSis reader, also from X-Rite.

Then we iterate this process. As we go along, we watch the dE between the actual values and the expected values get smaller and smaller

... and at the end of the process, we have over 1100 spot color definitions with 96% of them under 5 dE. Simple!

Another very cool feature of the Star Proof Packaging option is the ability to add spot colors by using an spot spectrophotometer, like X-Rite's i1. Read it, add it to the spot color list and you are ready to use it.

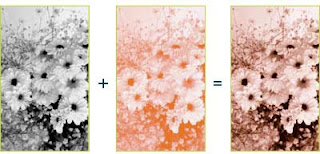

Think accurate duotones

Have you ever tried to proof a duotone? Star Proof can generate color precise duotones. With Star Proof your press operator can see a proof and know what inks make up a color. Try that with your average proof from a plotter.

Star Proof also enables you to assign the appropriate opacity to each spot color providing ultimate press simulation.

You may be thinking, why a dot proof?

Printing processes that use coarse screening or different screen ruling in the same job will have a major influence on its visual appreance and color gamut.

Actual dot per dot - right down to rosettes, fine line art, text at just 1pt, and even defects such as moire patterns.

Here's how a typical Star Proof workflow looks like:

Click on the image to see a larger view