Thursday, December 23, 2010

Season's Greetings

Thank you for being with us through out 2010. May you have a wonderful holiday season and that 2011 brings you peace, joy and prosperity.

As a present, Michael has prepared a holiday video card for you, enjoy.

Best wishes from all at Compose Systems

Thursday, December 02, 2010

Compose Releases Star Proof 6.5

We are proud to announce the release of Star Proof 6.5. Star Proof is Compose's dot per dot proofing solution. Capable of generating proofs up to 220 lpi. Star Proof does this by recombining 1 bit tiffs or ESKO LEN files. This new version of Star Proof brings compatibility to the new Epson Stylus Pro 3880, 4900, 7890 and 9890 plotters.

The Epson Stylus Pro 4900 is designed to offer professionals a powerful combination of performance, flexibility and ease-of-use. It includes automatic switching between roll and cut-sheet media, allowing users to have both the front paper cassette and roll feeder loaded with different media types and automatically switch between them with a simple driver selection. In addition, the high-capacity paper cassette holds up to 200 sheets of 8.5”x11” to 17”x24” sized sheets.

The Epson Stylus Pro 7890 and 9890 offer the same leading technology found in the Epson Stylus Pro 900-series, including ePlaten™ automatic media loading, spindle-free roll media loading, a roll media tracking system, front control panel with 2.5-inch color LCD, rotary cutter, fabric catch bin, and robust printer stand. The printers also feature Epson’s latest ink-repelling coating and auto nozzle verification technologies to virtually eliminate clogged nozzles, and use nine individual high-capacity ink cartridges up to 700 ml. In addition, these new models are capable of handling virtually any media type, in roll or cut-sheet. Both models are available with an optional SpectroProofer® spectrophotometer.

All these printers including the 3880 can swap black inks without having to remove any print cartridges. This is very important for those customers who switch back and forth between glossy and matte media.

Star Proof takes full advantage of the features included in these printers.

If you have any questions about this contact me directly or your Compose dealer.

Thursday, November 18, 2010

GapFinder II video demo

If you've still reading this, then you should watch the video below.

GapFinder is a production tool that allows printers to fully utilitize their web presses. It analyzes and re-arranges the job image so that the white portion of the image falls on the gap of presses’ cylinder, extends the printing height of your web presses.

Thursday, October 28, 2010

How to create PDF/X4 files from InDesign

On this video Michael Jahn shows how to create PDF/X4 files from InDesign.

Compose's Express RIP 8.3 is compatible with PDF 1.7 and PDF/X4. Which means if you follow the instructions on this video, your PDF files should RIP with out issues.

If you have any questions about this or on how to upgrade your RIP, please contact me.

Friday, October 22, 2010

Let's meet online

I hope to see you soon on one of our webinars.

Express Label Print: A smart way to print labels

Express Label Print delivers an outstanding performance solution to label printers. With its powerful, yet intuitive layout tools, it helps to shorten production time and reduce human errors. Express Label Print also includes a powerful cost analysis tool that not only calculates the cost of the print run, but also determines the amount of waste.

With the optional VariPrint module, Express Label Print turns into a robust variable data solution. Where you can specify text, and images as variables on your jobs.

Express Label Print is available on the new OKI 510DW printer. For more information visit OKI proColor or contact me directly.

Thursday, October 14, 2010

Live from the press room

I'm at a very large flexo printer in Mexico doing a Star Proof calibration. So far our result our results on the Epson WT7900 have been great. We are doing two calibrations, one on Epson Clear Proof Film, the other on Epson Metallic Proof Film. On the Epson Clear Proof we have over 97% of our Pantone® guide (1126 colors) matching. While on the Epson Metallic Proof Film we have over 90%.

The next step is to calibrate Star Proof to their presses. But before we get to that, we calibrated their press to G7. As I write this, we are are reading the values from the confirmation run. So far the numbers look great.

The idea behind G7 on a flexo press is to have a shared appearance with SWOP 3 and GRACoL. In other words, the idea is that what's printed on a G7 calibrated flexo press looks like things printed in other presses.

By the time I leave this customer, they will have their presses calibrated to G7, their proofer matching their presses and better Pantone® color accuracy on proofs than ever before.

Saturday, October 09, 2010

EWF supports DI presses from Prestek

EWF does this by taking ripped 1 bit files from it's own interpreter or from an outside RIP and turns them into color coded Presstek files, including a high quality preview file for the Presstek console.

Many of our customers running EWF with the Presstek module will add DI Proof to their setup. After a job has been processed by the Express Harlequin RIP, DI Proof picks up the separated raster data and generates a recombined contone PDF file. This PDF can be generated in different resolutions. A low res version can be sent to customers as a content proofs. A high resolution version can be sent to a proofer or viewed on screen. This raster PDF will be the same size with the same trapping, overprint, font and color information as the files that will end up printed on press.

If you have EWF and you are thinking about a Presstek system, all you need to do is acquire the Presstek module for your EWF. If in the other hand, you already have a Presstek, but you're running an older RIP and would like to bring your solution up to date, we have a solution for you. In any case, contact your Compose dealer or me directly for more information.

Thursday, October 07, 2010

What ISO12647standarization.com means for printers

Wherever there is manufacturing, there are standards. I can think of many examples to illustrate this. From clothing to food production. If there's to be consistency, predictability, then there needs to be a defined way to manufacture products. These manufacturing definitions are called standards.

At Graphexpo 2010, KEE consultants showed their ISO12647 Standardization initiative. On this video, Dave Hunter explains what ISO12647standarization.com means for printers.

The future of commercial printing industry will depend on its ability to adapt to the new market realities. Very soon, working to standards will become a requirement for all printers seeking clients beyond their neighborhood, as is the case for most manufacturing and production industries.

More than 400 printers are currently compliant to PSO/ISO 12647 and dozens are joining the list every month worldwide.

For more information e-mail me or visit iso12647standardization.com

Friday, September 24, 2010

Color Logic, Metallic inks for the rest of us

Their integrated system starts in the pressroom and is then communicated back to the designer. Most of the traditional color and metallic systems of the past would try to characterize all printers into the same box. For any color communication system to work in the real world you must take into account the key variables of paper, ink, plates, printing press and process control. The Color-Logic Process Metallic Color System will work with clients who print to standard printing conditions such as ISO™, G7™, GRACol™ or their own in-house printing standards.

Color-Logic provides the printer with a form for printing their own color guides. The printer then provides their designers, brand managers, and agencies with the Color-Logic metallic color guides printed in a known printing condition along with the Color-Logic Metallic Design Suite™. The Color-Logic Metallic Design Suite is compatible with all major design software programs. The suite has plug-ins with hundreds of metallic shades which correspond to the color guide provided by the printer.

For more information, please contact us or visit Color Logic's website by clicking here.

Wednesday, September 01, 2010

EasyBook is now 64 bit compatible

EasyBook is an ideal tool for printing jobs on a laser printer when the features of the manufacturer's print driver are not enough. Perfect for printing brochures, booklets and step & repeat business cards. You can create saddle stitched booklets, perfect-bound booklets, or 2-up print-outs with cut-and-stack, step-and-repeat or simple page pairing styles. It is designed to be easy-to-use and yet as feature rich for digital production. Unlike other simple booklet creation software which only offers basic capabilities, EasyBook offers advanced features such as support for creep, gutter, inner and outer spread, placement of crop marks, color bars and print labels.

Highlights

• Ideal booklet creation tools for digital color printers

• Fully supports PDF version 1.3 to 1.6.

• Output size up to 13 x 19 inches (330mm x 480mm)

• User defined code for easy identification of output

• Support wide range of booklet styles

• Automatic pages correction

• User defined margin

• Advanced marks setup

• Runs on Windows 7 and XP Pro

Contact your preferred Compose reseller or Compose directly, our e-mail is sales@composeusa.com

Friday, August 20, 2010

Printing Labels across the Pond

The Apex 1290 digital label printer is driven by Express Label Print, a nifty software solution from Compose. Express Label Print or ELP, can handle a multitude of different stocks and optimizes label layouts to reduce media waste. You can print on pre cut media or also import your CF2 die cut files for the best possible layout.

You can add variable data to your print jobs on the Apex 1290 digital label printer with Compose Variprint.

Below is a video of the Apex 1290 digital label printer in action:

On this trip I've also visited customers to talk about press calibration and the advantage of having presses and proofers matching common specifications and standards. I've also taken the opportunity to learn from my European colleagues about their experience with ISO 12647-2.

Simon, Tom and me at BHF in Dartford responding to our customer's questions.

Tonight I'll have pint thinking not thinking about the flight back to California.

Contact me if you have any questions about the Apex 1290 or anything else that catches your eye on this blog.

Friday, August 06, 2010

Doutone proofing on an EPSON using Star Proof

The first issue they faced was "how to I actually create a Doutone using two spot colors" - they thought this was the biggest challenge, but a quick screen recording movie while creating one in Photoshop showed how simple that was - you can see this here;

http://www.youtube.com/watch?v=eCtAUXAxugM&hd=1

The second issue - proofing this - seemed to be a breeze - they were confident that their proofing system was able to simulate the two spot colors very acutely, which was true, but what they didn't consider was the halftone screen angles - better said, they had no way to simulate the halftone screen angles, so the problem never reveal itself until they were on press, where problem revealed itself - disaster ! This is what the press sheet looked like;

Well, first, we helped them navigate to where they would go to set the screen angles in their RIP;

Thursday, June 10, 2010

With Star Proof 6 spot color matching is a breeze

Capable of simulating line screens up to 220 lpi, Star Proof is well known for reproducing the sharpest dots possible on an Epson proofer. Star Proof will show the same dot produced by your RIP on your proofer, in just the way they will show once printed on your press. But, did you know that Star Proof can reproduce spot colors with a high degree of accuracy?

The new EPSON Sylus Pro 7900/9900 and WT7900 offer an incredibly larger color gamut than previous plotters. This is due to the additional inks these plotters utilize. Orange and green on the Stylus Pro 7900 and 9900. And white ink on the WT7900. Star Proof 6 takes advantage of this larger color space to accurately reproduce spot colors. Calibrating Star Proof to do this, it's very easy with its optional Packaging Option. Here's how:

With the aid of X-Rite's color port, we create a target made up of all the spot colors that we wish to calibrate. Then we print it and read it using your favorite spectro device - in our case, we used the i1 iSis reader, also from X-Rite.

Then we iterate this process. As we go along, we watch the dE between the actual values and the expected values get smaller and smaller

... and at the end of the process, we have over 1100 spot color definitions with 96% of them under 5 dE. Simple!

Another very cool feature of the Star Proof Packaging option is the ability to add spot colors by using an spot spectrophotometer, like X-Rite's i1. Read it, add it to the spot color list and you are ready to use it.

Think accurate duotones

Have you ever tried to proof a duotone? Star Proof can generate color precise duotones. With Star Proof your press operator can see a proof and know what inks make up a color. Try that with your average proof from a plotter.

Star Proof also enables you to assign the appropriate opacity to each spot color providing ultimate press simulation.

You may be thinking, why a dot proof?

Printing processes that use coarse screening or different screen ruling in the same job will have a major influence on its visual appreance and color gamut.

Actual dot per dot - right down to rosettes, fine line art, text at just 1pt, and even defects such as moire patterns.

Here's how a typical Star Proof workflow looks like:

Wednesday, June 09, 2010

Introducing File Distribute

Wouldn't it be nice if the workflow could look at the file name and know what to do? Well, Express Workflow is smart and just knows. It's that smart.

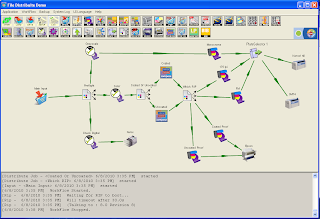

Introducing File Distribute

File distribute is a EWF module that routes jobs according to it's file name. All you have to do is add to the PDF file name what you want done to the job and EWF will take care of the rest. Best of all, you get to decide what file naming convention works for best for you. The workflow below uses the File Distribute module three times to get the job done. The first thing it does is route the file to the appropriate PitStop Server module depending if the job is for our digital press, grayscale or color. If the file is color, the next routing module will decide if the job is going on coated or uncoated paper on press. Depending on this the file will get sent to the IS Optimizer module that will apply the right dot gain and the total ink coverage the job should have depending on the paper it will be printed on. The next module routes the job to the proofing RIP or the final output RIP. If the job is set to the final output RIP modules, after the job is ripped the EWF Plate Selector module analyzes the plate size and routes the job to the appropriate input folder of our CTP device.

For example, if we want a color job, named "ABC.PDF" to go on coated paper at 175 lpi on our Komori press. All we need to do is change our job name to "ABD-C-C-175.pdf" and EWF will process this job according to to these instructions.

File Distribute is one of over 50 modules available on EWF 3. To activate File Distribute on your EWF or to learn more about it, contact Compose or your Compose dealer. If you have an earlier version of EWF, now it's the time to upgrade. Support rates for configuring your workflow will apply. Click on the image below to see it larger.

Saturday, April 24, 2010

Words from our new guy

My name is Michael Jahn, and I will be part of the support team for North and South America for Compose.

I have worked for prepress service providers, directed a prepress facility for gravure and heatset off set, worked for prepress solution developers like Agfa and Enfocus and worked with Pantone on a hexachrome for flexography project, all of which made me better understand the process between a designers idea and a printed sample.

I am tasked with helping existing customers keep their Compose solution working smoothly and reliably as well as help set up, install and train new customers. Compose offers a wide variety of easy to set up workflow tools, but as you know, it is paying attention to the dialog boxes, set up and software settings that makes for smooth operation.

Feel free to contact me directly by email michaelejahn at composeusa.com with your questions, concerns or comment, and I will do my level best to find the answers or work arounds - as someone who worked in the trade on projects with firm deadlines, I appreciate and respect your level of urgency !

Friday, April 23, 2010

Calibrating a Fast Press

The paper being used on press was type 1. The press' CMYK Lab values were within the GRACoL ICC profile and ISO tolerances. However, the RGB values were quite off. I configured our Ink Optimizer to have GRACoL was the input color space (profile). As for output, I used the ICC I created for the customer. This makes all jobs, processed by our ink optimizer and printed on the customer's press, to look like they were printed on a G7 calibrated sheet feed press.

The results were very impressive, no more plugged shadows. Colors were bright and crisp. We printed a sample job that uses well known images and they matched the GRACoL samples I had with me. The customer was very happy, so was I.

Have you though about calibrating your press? Give us a call and we'll help you get there.

Wednesday, April 21, 2010

Sample print on the Epson WT7900

Alvaro

Thursday, February 18, 2010

The new Epson Stylus Pro WT7900 is here and Star Proof is ready

This image was printed on clear film on an Epson Stylus Pro WT7900. What makes it different from other prints done on other plotters? Well, if you look at the flying dove, or the guy's checkered shirt, you'll notice that there's white. But wait a minute, wasn't this printed on clear film and the background is certainly not white. How can this be?

Let me introduce you to the new Epson Stylus Pro WT7900. And you guess it, it can print white ink. What makes this new printer more interesting, if you are say involved in flexo printing or part of the packaging industry, is that Star Proof can drive it. As you may know, Star Proof is a dot per dot proofing system. Meaning that it can reproduce the same halftone screen patterns that will end up on press. Star Proof can provide very accurate color proofs with dots and with this new printer, with white dots!

You can click on any of the images on this post to see them bigger.

Call your Compose dealer or us directly at (916) 920-3838 for a printed sample.

Call your Compose dealer or us directly at (916) 920-3838 for a printed sample.